Are you struggling with time-consuming and labor-intensive manual inspection processes in your manufacturing operations? These processes can be prone to human error, potentially leading to significant product quality issues.

That’s where visual inspection AI (artificial intelligence) can help. It is a critical component of the manufacturing process that ensures quality products while reducing the risk of human error. AI-powered computer vision applications can automate and enhance manufacturing inspections, saving time and costs while improving accuracy and consistency.

The global market for visual inspection AI in manufacturing is expected to reach $2.2 billion by 2027, growing at a CAGR of 7.3% from 2020 to 2027. – Grand View Research

What is visual inspection AI and how does it work

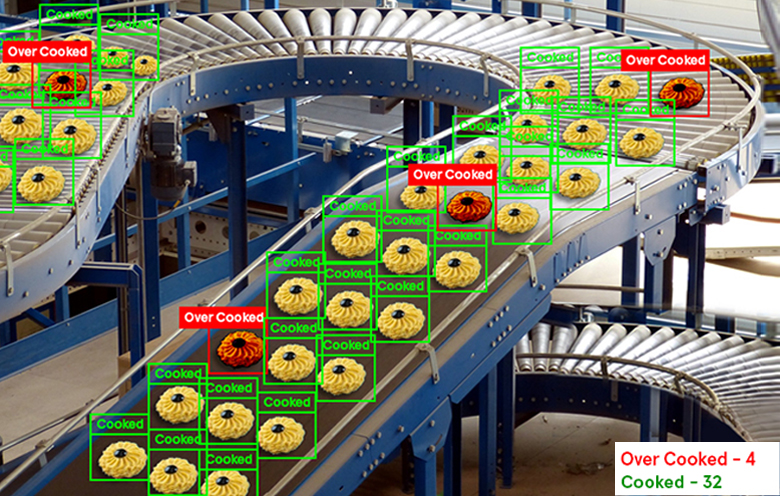

Visual inspection AI is a technology that uses AI and computer vision to automate inspections in industries like manufacturing.

The process involves capturing images or videos of products or materials using cameras and sensors. When you use AI algorithms in manufacturing, the images are automatically analyzed using machine learning models. AI technology can quickly and accurately identify defects or anomalies in the production line, helping to resolve issues efficiently and effectively.

Your ML models are trained on large datasets to identify patterns and anomalies in images. As the system processes more data, it becomes more accurate and efficient at detecting defects and anomalies.

Visual inspection AI is one of the latest computer vision trends in the manufacturing industry. It offers numerous advantages such as enhanced efficiency, reduced human error and improved quality control in manufacturing processes.

What are the benefits of AI in manufacturing through visual inspection

Visual inspection AI in manufacturing has several benefits for you, including:

- Increased accuracy: You can achieve high accuracy and consistency in defect detection by utilizing computer vision applications for visual inspection. It is often challenging to accomplish through human inspection alone. This results in fewer false positives and negatives that allows manufacturers to identify and address issues more efficiently.

- Reduced costs: Automating the inspection process with visual inspection AI can help you lower labor costs related to manual inspection. Additionally, catching defects early in production can result in lower scrap rates and rework, saving on materials and resources.

- Improved efficiency: Implementing computer vision systems for quality control in manufacturing can have significant benefits. AI can boost manufacturing efficiency with predictive maintenance, quick inspections by quality QC and reduce downtime.

- Enhanced safety: In some cases, visual inspection AI can reduce the need for manual inspection by quality managers in hazardous environments, improving workers safety.

For example, a semiconductor manufacturer in Taiwan reported a 10% reduction in scrap rates and a 50% increase in throughput after implementing a visual inspection AI system.

For example, a manufacturer of automobile parts in Japan reduced labor costs by 30% and achieved a 95% defect detection rate by using a visual inspection AI system.

Using AI-powered computer vision, you can easily identify and address defective products, meet production demands and maintain high-quality standards. This ensures your manufacturing processes run smoothly with minimal interruptions.

For example, a packaging manufacturer in the US reported a 50% reduction in inspection time and a 10% reduction in labor costs after implementing a visual inspection AI system.

For example, the BMW Dingolfing plant in Germany uses Visual AI to monitor the factory floor for safety hazards. The system detects when workers aren’t wearing required PPE or machines operate outside normal parameters and alerts the safety team. This has helped reduce accidents, injuries and increase efficiency.

While we have explored its benefits and real-life examples, it is critical to also consider how other companies use this technology in their manufacturing operations.

A complete guide to computer vision for quality control in manufacturing

Whether you want to learn how to design a computer vision system for quality control (just by following six steps) or know how to use computer vision solutions for quality control in manufacturing, your answers are just a download away from this whitepaper.

Real-life applications of computer vision for visual inspection in manufacturing

Here are a few manufacturing brands using CV for visual inspection AI in manufacturing and the results they have achieved:

- Foxconn: The world’s largest electronics manufacturer implemented visual inspection AI and reduced inspection time by 30%, while improving accuracy by 80%.

- Bosch: The German engineering and technology company implemented computer vision and machine learning algorithms to inspect automotive parts and achieved a 10% increase in production efficiency.

- GE: The American multinational conglomerate uses visual inspection AI to detect defects in aircraft engines and other critical components. This has led to a 25% reduction in inspection time and a 30% reduction in manufacturing costs.

- Flex: The Singaporean electronics manufacturer uses computer vision and machine learning algorithms to inspect printed circuit boards. This has resulted in a 90% reduction in inspection time and a 99% reduction in false positives.

- Siemens: The German multinational conglomerate uses AI to inspect wind turbine blades for defects. This has led to a 30% increase in inspection accuracy and a 50% reduction in inspection time.

We have seen how some well-known brands use computer vision applications for visual inspection to enhance their manufacturing operations. However, implementing visual AI using computer vision can also come with its own set of challenges. In the following section, we will explore these common challenges and discuss possible solutions to overcome them.

What are the challenges of using CV for visual inspection in manufacturing and how to overcome them

1. Technical issues: Implementing visual inspection AI requires expertise in machine learning and computer vision, which may be outside the scope of some manufacturing companies.

Solution: Partnering with a computer vision services provider can help manufacturing companies overcome this issue in implementing visual inspection AI.

2. Quality and accuracy of data: One of the major challenges in implementing visual AI is ensuring the manufacturing quality and accuracy of the visual data being used for training the algorithms.

Solution: To address this challenge, manufacturers can use high-quality and diverse training data to train the algorithms, which can help improve their accuracy.

3. Integration with existing systems: Integrating visual AI into manufacturing systems can be challenging due to complexity and time consumption.

Solution: Manufacturers can work with experienced technology partners who have expertise in integrating visual AI with existing systems.

4. Cost: Visual AI implementation can be expensive, especially for smaller manufacturers.

Solution: A cost-effective way to implement visual inspection AI is to start with critical areas and gradually expand. This reduces costs and ensures efficient use of resources.

5. Ethical concerns: There are ethical concerns associated with the use of visual AI, such as potential bias and privacy issues.

Solution: To promote responsible and ethical use of visual inspection AI in manufacturing, use transparent and accountable AI practices. This helps build trust with stakeholders and ensures that the AI is used responsibly. By doing so, manufacturers can build trust with stakeholders and promote the responsible use of AI.

Manufacturers can achieve improved operational excellence in manufacturing by addressing challenges and implementing visual AI using computer vision.

Getting started with Visual Inspection AI

Visual inspection AI has transformed manufacturing by improving quality control methods, efficiency and cost savings. To stay ahead of the competition and thrive in the years ahead, every manufacturer must invest in this technology.

Partnering with a computer vision service provider can maximize visual inspection AI for quality control in manufacturing. Contact us to learn how you can leverage the benefits of AI with your business model.