Industry 4.0 wave

While the Industry 4.0 revolution has gained momentum and many organizations are exploring new ways to leverage IoT with expectations to enhance business processes and overcome existing challenges, there are many questions people have around IoT implementation with the existing infrastructure. At present, one of the burning questions in the market is “will IoT replace Supervisory Control and Data Acquisition (SCADA) in a new era for manufacturing?” Such questions not only help industrial companies understand the future relevance of current technologies but also help them take near-term automation investment decisions.

Manufacturing is already a mature industry and technology has paved the way since long for improving manufacturing processes with prevalent systems like SCADA. Since there is a new tidal wave of data emerging from IoT, what role existing systems like SCADA will play is something everybody wants to know. SCADA has helped many industries including manufacturing to monitor and control their processes and industrial applications, which has resulted in decreased operational costs and increased efficiency. But with growing technological advances, people are concerned about increasing costs and infrastructural changes posed by implementing the new technology.

Is old machinery a roadblock? Here’s how to transform them into smart machines

Webinar agenda

- Current manufacturing scenario

- Turmoils with old machinery

- Why is the existing monitoring system (e.g., SCADA) not enough?

- How IIoT and edge analytics add value?

- Value realization with IIoT ecosystem

- How to quick start with IIoT

SCADA – then and now

First of all, let’s take a brief look at how SCADA works. It is an end-to-end system that receives data from Intelligent Electrical Devices (IEDs) or Remote Terminal Units (RTUs), which are connected to sensors through a communications network. The system then analyzes this data and sends commands back to the field, with individual SCADA applications often working simultaneously. In early days, the system was used to control and monitor processes via costly and sluggish mainframe computers, which initially laid the foundation for data logging technology. With the introduction of advanced graphical user interfaces (GUIs) and mass configuration tools, it became more efficient and accurate. Today, SCADA is used across various industries, for example, the mining industry uses SCADA for monitoring environmental parameters, the oil and gas industry uses it for real-time monitoring of pipelines and extraction processes from a remote location, and railways use it to manage communication, control traction power supply, and implement train control automation.

Next phase of manufacturing- Has SCADA had its day?

The good news is that SCADA is here to stay and the Internet of Things is the next phase of smart manufacturing that upgrades SCADA by making it more intelligent and smart. IoT complements both distributed control system (DCS) and SCADA by widening existing capabilities like real-time data capturing, anomaly/machine breakdown alerts, real-time control, data logging, data analysis, and visualization.

Let’s see how IoT takes SCADA systems to the next level

| Traditional SCADA | IoT takes it to the next level | |

|---|---|---|

| Autonomous commands | Data aggregation | |

| Remote monitoring | Predictive analytics (what will happen in the future) | |

| Supervisory control | Prescriptive analytics (What you should do) | |

| Alarms and alerts | Data creates value in multiple applications | |

| Reporting | Enabling new business models | |

| Decrease operations and maintenance costs |

SCADA systems have been doing a great job in monitoring and controlling industrial- and facility-based processes that exist in the physical world, but IoT can process your data and bring the intelligence and insights hidden within it.

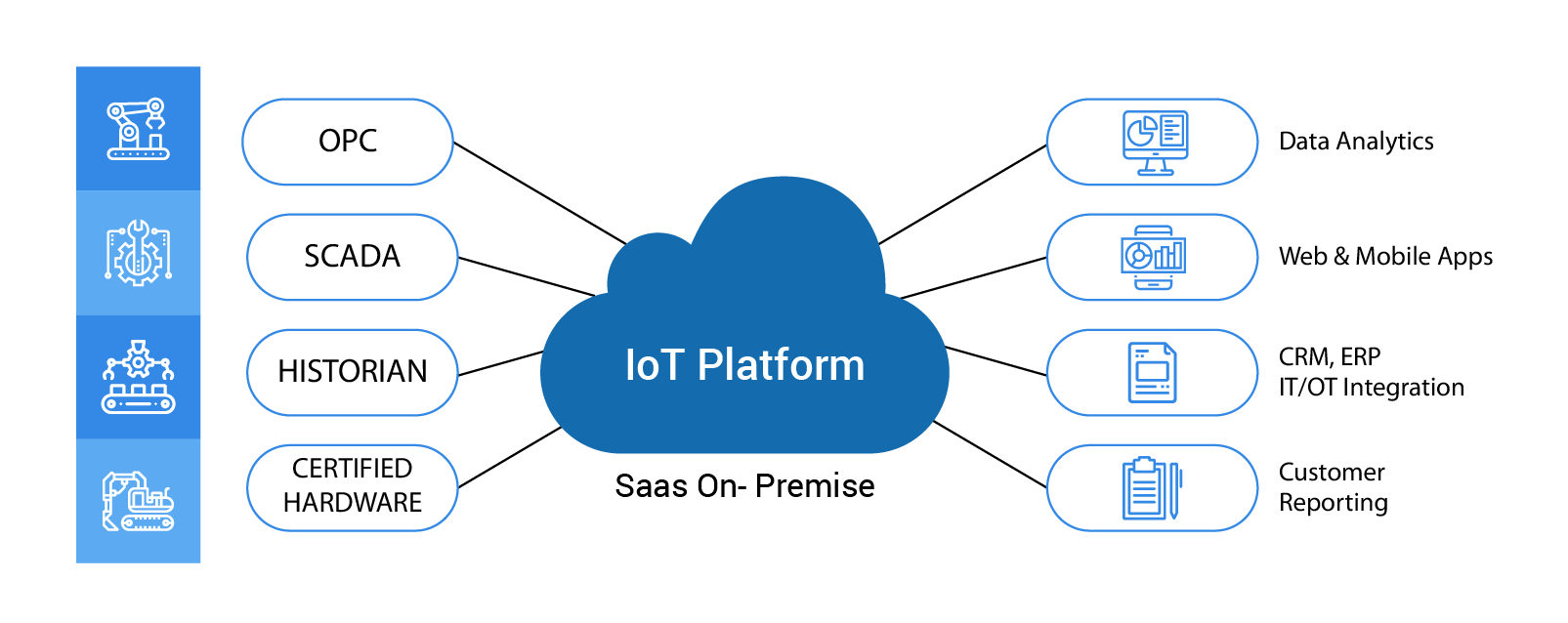

With the growing number of connected devices, the need for gathering, exchanging and analyzing data has substantially increased. Industrial companies have started observing a growing need for increased interoperability and information transparency to stay ahead of the competition and cut operational costs. Currently, many ISVs provide an IoT platform that is hardware agnostic and use SCADA and other traditional systems as a data source wherein security and supervisory control are not compromised but enriched within existing infrastructure. Open and secure connectivity options such as AMQP, MQTT, REST, and OPC UA Pub/Sub make such a merged IoT architecture. While SCADA’s focus is on controlling and monitoring machines, IoT’s focus is on analyzing machine data to increase efficiency that directly impacts a company’s bottom line. SCADA works as secure IoT Gateways (or call it Message Oriented Middleware (MOM)), which enables companies to connect edge devices across multiple sites and bring data on a single platform to perform analysis for making better decisions.

At the same time, one should also understand that SCADA has some limitations and that can be overcome with IoT. For example, factories are heterogeneous by nature and it is difficult to manage the disparate nature of the industrial digital ecosystem from a single place. This is where IoT comes into play as it fosters interoperability and data transparency.

Conclusion

Digitization is changing the way manufacturing companies work but SCADA will still be useful in terms of collecting and monitoring the day-to-day operations of a factory or process. IoT empowers SCADA systems and helps manufacturers store an infinite amount of historical data in the cloud for deeper analytics that bring out hidden information to solve long time unresolved problems.