In this energy-intensive world, the demand for electricity is ubiquitous. To run commercial, industrial and household premises, we source energy from electricity grids. Power outages, load shedding and other main supply anomalies result in intermittent breaks in the electricity supply. A diesel generator (DG) set is the primary go-to arrangement in such a scenario.

DG sets enable organizations to continue their business in case of a power failure and help in circumventing expensive downtime. Generators, however, have become an expensive asset to operate for most organizations as it is not well maintained. In reality, if well managed, maybe by using diesel generator monitoring solution generators provide years of reliable service.

Therefore, allowing generator owners to run their generators at peak efficiency, for the longest possible amount of time, can improve the bottom line of their business. In this blog, we will portray some of the metrics that directly impact DG sets’ effectiveness performance.

It is evident that if you’re trying to use sensors everywhere, you’re going to get nowhere because it’s too imprecise and too costly. One should choose the locations where IoT solutions can make information visible and generate operational advantages like never before. That is the key to a good IoT deployment.

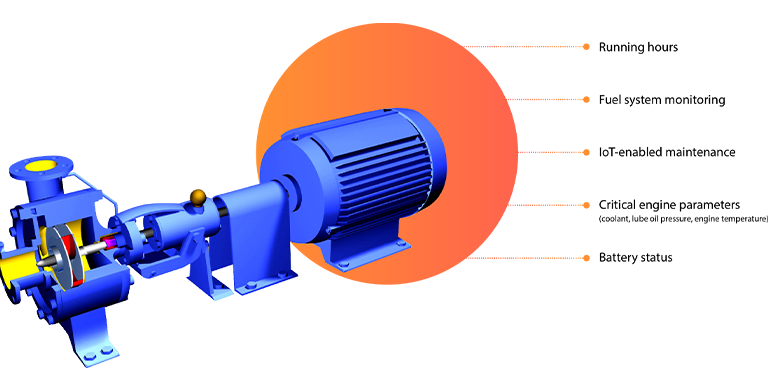

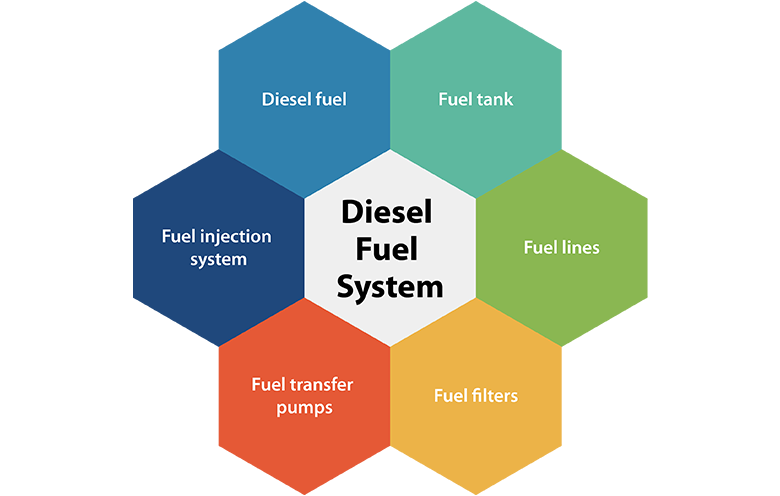

Following are some parameters that can run to its highest efficiency when a DG set is monitored.

Running hours

One of the most important parameters to monitor accurately is the amount of time the DG set runs. Because DG sets are used for a wide range of purposes, studying its operating hours help to understand the DG’s usage patterns.

Fuel system

To comprehend a DG’s general effectiveness, diesel must be tracked because it is subjected to contamination and corrosion within a year. Moreover, the fuel quality varies from country to country which can impact the performance of a DG set. To get the best quality of diesel, filtration systems are added in a DG set. Nevertheless, blocked fuel filters can raise specific fuel consumption (SFC) by 2gm/kWh. SFC is a measure of efficiency that relates fuel input and power output of a DG set.

Smart Diesel Generator Monitoring Solution

Diesel generators have become a vital part of almost every business infrastructure. For seamless business continuity, DG sets play a crucial role by providing back up during power failures that may result in lost productivity.

Further, did you know?

- Improper cooling water system can boost fuel consumption by up to 3%.

- A poorly kept fuel injection pump can increase SFC by 4gm/kWh.

- Irregular lubrication maintenance can elevate SFC by up to 0.5%.

- A defective nozzle can lift SFC by 2gm/kWh.

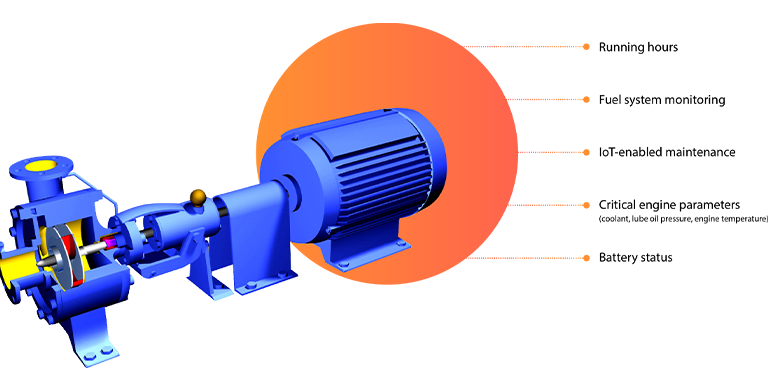

A fuel system has to be closely monitored as it helps to understand and elevate the overall efficiency of a DG. The role of the diesel fuel system is to inject at the appropriate moment an exact quantity of atomized and pressurized fuel into each engine cylinder. When this fuel rush is blended with warm compressed air, combustion happens in a diesel engine.

Following components make the diesel fuel system:

Each of the mentioned above fuel system components needs to be maintained well for allowing a DG set to work at its best.

IoT-enabled maintenance

For a DG set, it is not suitable to simply schedule a routine check-up ever so often. If nothing specific needs to be addressed, it is not the most effective use of maintenance engineers’ time. And if something needs to be addressed, there is always the risk that it could have happened weeks ago so it might have become more expensive. Hence, smart maintenance provides DG set a competitive advantage.

The key, then, is to implement gateways that read protocols from programmable logic controllers (PLCs) that control generator sets and enable remote generator monitoring. Information needs to be sent from PLCs to cloud-based devices that can analyze it, providing a real-time perspective of how critical elements of DGs are performing. When specific requirements are met, tailor-made alerts and alarms can be initiated, allowing executives to determine instantly when a tiny issue occurs and maintenance needs to be planned. In turn, maintenance can be scheduled for particular low-demand periods, decreasing downtime and optimizing consumables such as oil. Industry reports indicate that an active program of electrical maintenance can reduce outages by more than half.

Such predictive or condition-based maintenance provides OEMs with the least costly and most effective way to reduce downtime associated with the DG set.

Using IoT, you can monitor day-to-day engine efficiency, carry out 24/7 fuel tank monitoring to detect fuel theft, maintain permissible emission limit and ensure the right refueling quantity to prevent stoppage.

Critical engine parameters (coolant, lube oil pressure, engine temperature)

Coolants are used to control engine temperature and avoid engine rusting. If not fixed in time, the drop in coolant concentrations leads the DG to overheat and can cause irreparable harm to the DG set.

Battery status

Weak or undercharged starting batteries are a common cause of mistakes in standby power systems. The battery must be maintained at an optimum charge level to avoid dwindling and to prevent any generator start-up hits. Periodic testing and inspection are considered the best way for it.

But merely checking the batteries’ output voltage is not indicative of their capacity to provide sufficient starting energy. Its age, cleaning standards, specific gravity of the electrolyte in each battery cell and electrolyte level – all matter. Because, as batteries age, their internal resistance to current flow increases, so precise measurement of terminal voltage under load is required. Nowadays with IoT, this indicative test is carried out automatically on some generators every time they start.

In conclusion, IoT solutions can make information visible and generate operational advantages like never before. With a diesel generator monitoring solution, you can minimize overall CAPEX and maximize ROI.