The manufacturing industry has always been at the forefront of technological advancements. The advent of the industrial metaverse has given manufacturers an opportunity to embrace a new era of innovation. This can enhance collaboration, visualization and training. The industrial metaverse is a virtual environment that allows geographically dispersed teams to work together in real time.

As per a report published on metaverse industry by Strategic Market Research, the global market value is expected to surpass $678.80 billion by 2030 at a CAGR of 39.44%.

It helps them visualize complex manufacturing processes and equipment, and trains employees in a safe and controlled environment. The manufacturing industry can leverage the industrial metaverse to optimize production, reduce costs and improve efficiency.

The emergence of the metaverse is transforming the way individuals and organizations interact to produce, purchase, sell, consume, educate and work together. This paradigm shift is expected to bring exceptional advantages to the manufacturing industry.

In this blog, we will talk about the role of virtual and augmented reality in the industrial metaverse. We will also discuss the benefits of the industrial metaverse and its impact on traditional manufacturing processes.

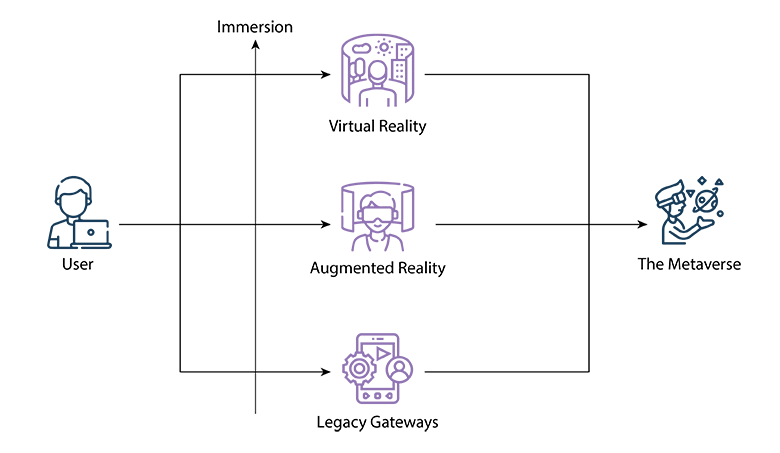

How virtual and augmented reality technologies contribute to the industrial metaverse

The introduction of virtual and augmented reality (VR/AR) has revolutionized the industrial metaverse. These technologies have enabled companies to:

- Create immersive, interactive experiences to train employees

- Simulate complex processes

- Provide customers with an engaging experience

The use of VR/AR can improve collaboration between teams in different locations, allowing them to interact with one another in a virtual environment.

With the increasing use of VR/AR technologies in developing industrial metaverse applications, companies can increase productivity and efficiency while providing a more enjoyable experience to their customers.

Here are some specific roles that VR/AR play:

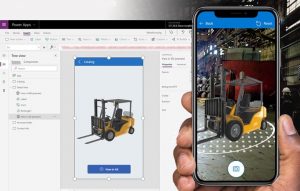

Design and prototyping: VR/AR technologies help designers and engineers create and test prototypes in a virtual environment before producing them physically. This reduces the prototyping time and cost and facilitates better collaboration among teams.

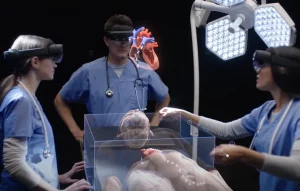

Training and simulation: VR/AR can be used for immersive training and simulation experiences, allowing workers to practice tasks and procedures in a safe and controlled environment. This would increase efficiency, reduce errors and minimize the risk of accidents.

Maintenance and repair: AR can provide real-time guidance and support to workers performing maintenance and repair tasks on machinery and equipment. This improves the accuracy and speed of repairs, reduces downtime, minimizes travel costs and enables faster response times.

Overall, these technologies can enhance productivity, safety and collaboration in the industrial metaverse. As these technologies continue to evolve, their potential applications in the industry will increase.

The applications of VR in the industrial training are numerous, click here to explore the top five VR applications in industrial training.

The role of the Internet of Things in the industrial metaverse

IoT plays a significant role in the development of the industrial metaverse. It provides real-time data on the performance of machines, equipment and processes. IoT devices can be integrated into a wide range of industrial equipment, such as sensors that monitor temperature, pressure and vibration.

IoT devices gather real-time data from various sources, such as sensors and machines, and send it to a digital twin model for analysis and simulation. By using IoT sensors to collect data from physical objects in the real world, digital twin models can create a virtual replica of the physical object. This allows for better monitoring, optimization, and analysis of industrial processes.

In the industrial metaverse, digital twins can be connected through IoT networks, creating a comprehensive digital ecosystem. This interconnection allows for seamless communication between various digital twins and real-world devices, enabling a more comprehensive view of the entire industrial process.

IoT provides the real-world data necessary for digital twin models to accurately simulate and optimize industrial processes, making it a critical component of the industrial metaverse. By leveraging IoT technology, the manufacturing industry can improve efficiency, reduce costs and increase competitiveness in the global marketplace.

Benefits of implementing metaverse in industrial manufacturing

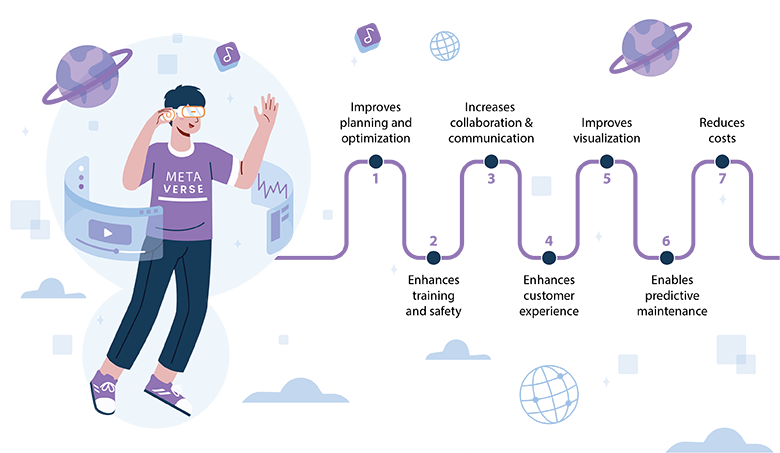

1. Improves planning and optimization: By visualizing the production process in a virtual environment, manufacturers can optimize their processes, identify bottlenecks and inefficiencies. This will help make modifications before deploying them in the real world. It would also result in more efficient production, better resource utilization and reduced downtime.

2. Enhances training and safety: Manufacturers can provide immersive training to employees on operating and maintaining equipment and machinery, without exposing them to real-world risks. This can also help ensure safety compliance and reduce workplace accidents. Virtual training can also be repeated as many times as needed without risk to physical equipment.

3. Increases collaboration and communication: Different teams across departments and locations can collaborate and communicate more effectively, by sharing a common digital workspace. By creating a virtual environment where team members can interact and work together in real-time, the metaverse can eliminate physical distance barriers and enhance collaboration. This can lead to better decision-making, faster problem resolution and improved productivity.

4. Enhances customer experience: Manufacturers can use the industrial metaverse to showcase their products and services to customers in a visually engaging way, using AR and VR technologies. This can help attract more customers, enhance their experience and increase sales.

5. Improves visualization: The industrial metaverse can provide an immersive and interactive way to visualize complex manufacturing processes and equipment. This can help engineers and operators better understand machinery and processes, identify potential issues and optimize production.

6. Enables predictive maintenance: The industrial metaverse can also be used to monitor equipment performance in real-time and predict when maintenance is needed. This reduces downtime, improves productivity and extends machinery lifespan.

7. Reduces costs: By leveraging the benefits of the industrial metaverse, manufacturers can reduce travel, physical prototyping and equipment maintenance costs.

The use of Industry 4.0 technologies like AI, ML, edge computing and XR will facilitate digital transformation for organizations, resulting in revenues of $22.73 billion for industrial digital twin, simulation and XR by 2025. – ABI Research

The impact of the industrial metaverse on traditional manufacturing processes

The industrial metaverse has the potential to transform traditional manufacturing processes in several ways. Here are a few potential impacts of metaverse in manufacturing:

1. Simulations ahead of physical deployments help in improvements: Virtual simulations can help manufacturers identify potential issues and optimize their manufacturing processes before they deploy them. This would save time and resources in the long run by reducing the risk of errors or faulty designs.

2. Using AR/VR to help field service workers fix equipment on the job: Field service workers can use AR/VR to access digital manuals, 3D models and live video feeds to diagnose and repair equipment on the job. This can increase efficiency and reduce downtime for manufacturing facilities.

3. Building physical products from virtual designs; adding digital assets from physical items: Manufacturers can build physical products directly from virtual designs by using technologies like 3D printing. Additionally, they can add digital assets to physical items to track their performance, location and maintenance needs, providing valuable data for manufacturers.

Metaverse is not only impacting manufacturing but several other industries, take a look.

Let metaverse shape the future of your manufacturing enterprise!

The industrial metaverse is set to revolutionize the manufacturing industry in many ways. By leveraging cutting-edge technologies such as VR/AR, IoT and advanced data analytics, companies can create a more connected, efficient and innovative manufacturing ecosystem. As the metaverse continues to evolve, it will create new opportunities and challenges for manufacturing enterprises.

Therefore, businesses must embrace this transformation and leverage its potential to drive growth and success in the digital age. With the help of the industrial metaverse applications, manufacturing companies can unlock a world of new possibilities and shape the future of the industry.

The metaverse represents a new era of digital transformation for the manufacturing industry to gain a significant competitive advantage in the years to come. So, let the metaverse shape the future of your manufacturing enterprise. For more information on metaverse in industrial manufacturing, please talk to our experts!