The Industrial Internet of Things (IIoT) is practiced through numerous industries like manufacturing, logistics, transportation, energy/utilities, oil and gas, aviation and other industrial sectors. It integrates machine learning and big data technologies to utilize the sensor data, automation technologies and machine to machine communication. The driving values behind IIoT are accurate and constant capturing and collaboration of real-time data with the process.

It is mainly aimed at combining machines, producing data, performing analytics and acquiring useful insights for enabling the user to take proactive actions in order to improve operations in industries. IoT fetches data from all the sources, sends it to the cloud and with the help of data analytics, it is visualized for obtaining useful insights.

Industrial Internet of Things focuses on the improvement of the operational competences, automation, efficiency, and maintenance. It unlocks abundant opportunities in automation, optimization, smart manufacturing, and asset monitoring.

The main components in the construction of IIoT are:

- Data procurement from numerous sources- The data is collected from numerous sources with the help of sensors that are attached to the devices.

- Communications, networking, and security- The transmission of information happens from the sensor to control system to cloud applications.

- Cloud applications- IoT cloud provides you with tools to collect, process, manage and store enormous data in real time.

In the current scenario, organizations are concentrating more on digital and cloud

Digitization of the business process and adoption of the cloud are two main criteria for which the organizations are transforming themselves. As per the present market demand for automation, these transformations have to leverage the power of the Internet of Things for better results.

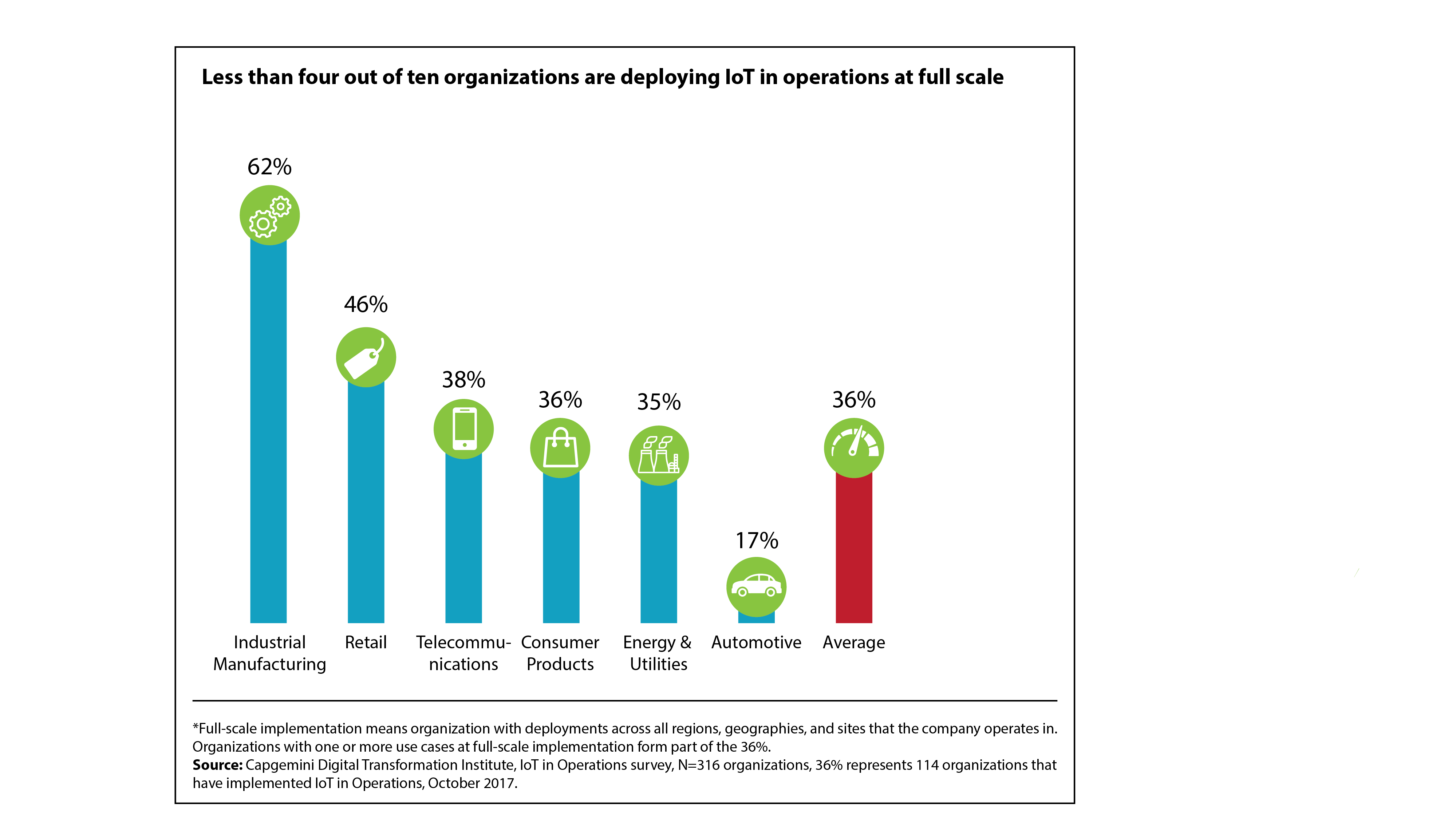

Facts about the use of IoT in industries today

- 30% of enterprises use IoT products today while 65% are expected to use it by 2020.

- 30% of the overall IoT market ($300B/year) will be IIoT ($85B/year).

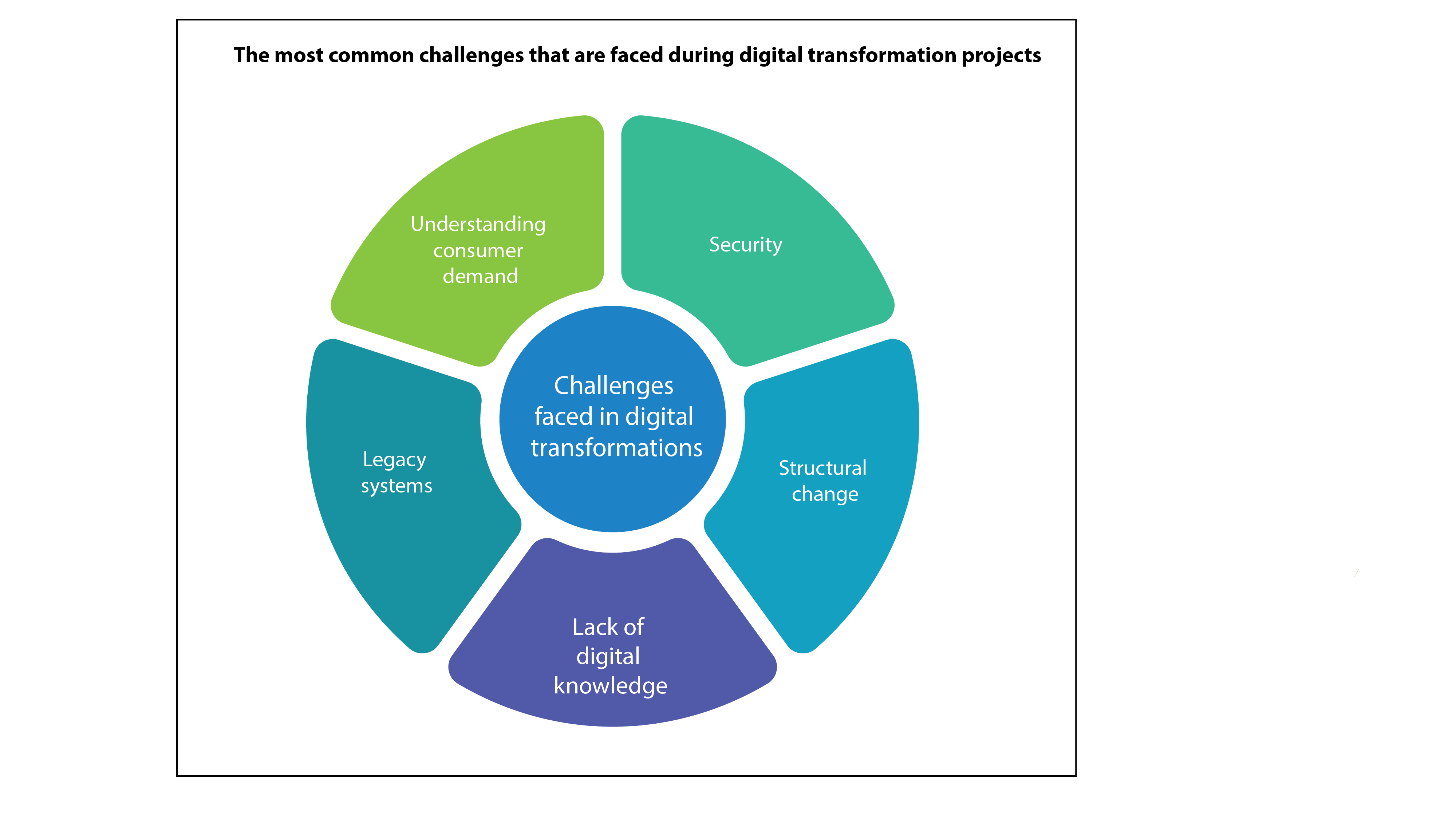

The most common challenges that are faced during digital transformation projects

IIoT offers several opportunities that can be used to overcome the above-said challenges. By analyzing the huge amount of data produced by devices, the organizations can make better business decisions. At times the action can be taken on devices while in other cases, it can be regarding the robotic process automation. With the help of technologies and applications like artificial intelligence, machine learning, blockchain, and other supportive technologies, a connected, augmented, and smart ecosystem can be generated for business improvements.

IIoT has several prospects for organizations, they are:

- scaling operations

- managing risk for workers and equipment

- improving procedures

- managing the structural setup remotely

- real-time tracking

- continuous monitoring

- automation

- fetching useful insights from data

- the convergence of information technology and operational technology

- implementing security obedience

The above-mentioned prospects can help upcoming programs for digital transformations in connecting the devices to the internet.

On the other hand, edge computing is also in focus these days due to its capability of supporting the scaling of the ecosystem. Some of the benefits of edge computing are:

Real-time data analysis – This is because the data is analyzed at the local device level.

Smaller operating costs – Since the data management expenses of local devices are less in comparison to clouds, the operating costs are less.

Less network traffic –The data is transmitted from local devices via a network to cloud and that result in reducing the network traffic.

Improved application performance – The applications that do not tolerate latency, can acquire lower latency levels on the edge and that improves their performance level.

These advantages give an idea that edge computing has the potential to become a mainstream technology sometime in the near future.

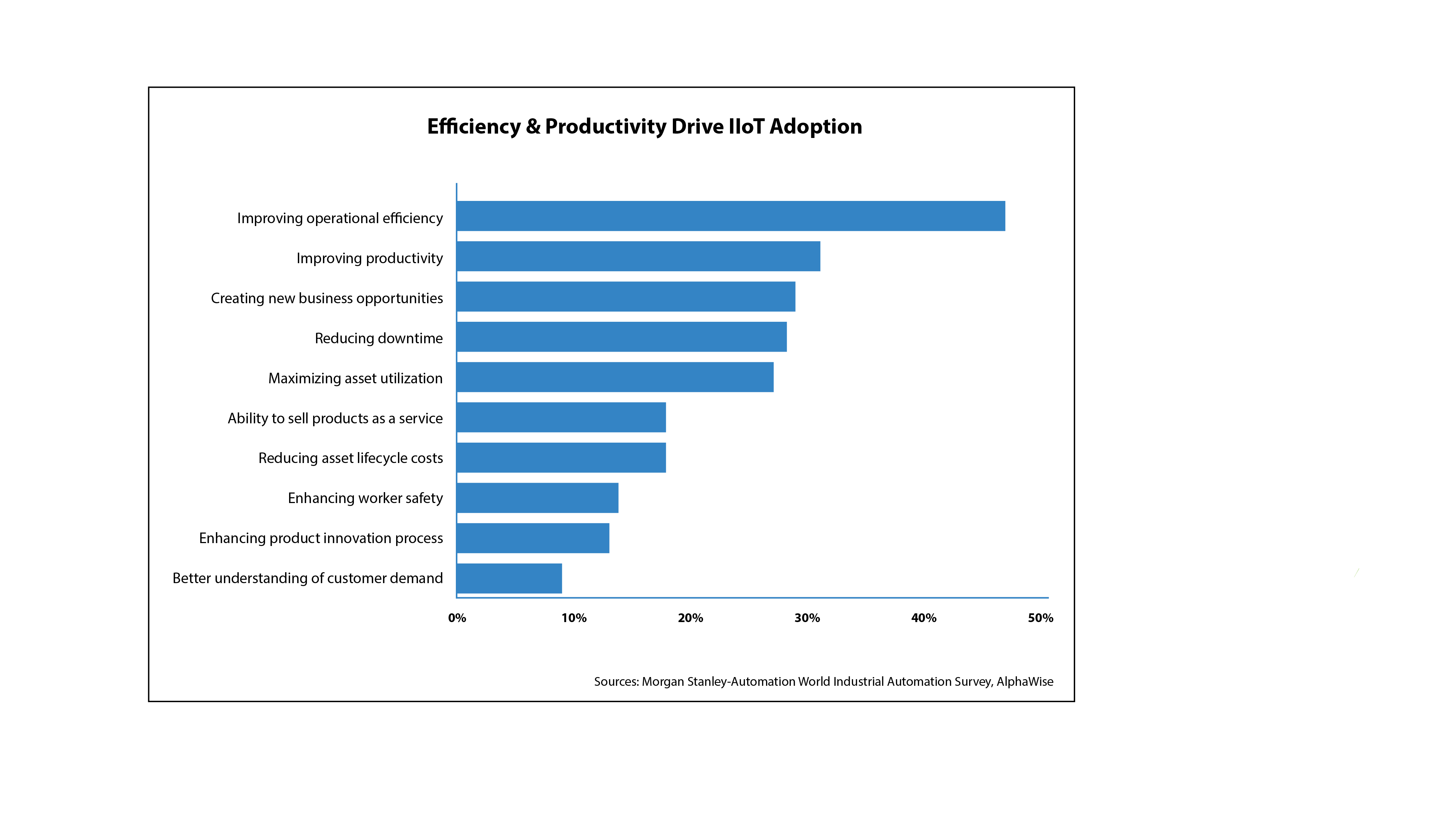

According to a 2015 survey of about 200 automation executives conducted by Morgan Stanley (an American multinational investment bank and financial services company) and Automation World magazine, the following chart shows the most important drivers among manufacturers for adopting IIoT.

Use cases

- IIoT is highly beneficial due to its capability for performing predictive maintenance. This includes the use of real-time data generated by IIoT by the organizations to predict the probable defects before they occur, which allows them to address those issues before any machinery gets damaged.

- IIoT helps field service technicians to recognize probable problems in equipment before they grow into big troubles, empowering technicians to resolve the problems beforehand.

- Another perk of IIoT is asset tracking. Customers and manufacturers can use this system to track their assets for its location and condition. The system sends alerts to the manager in case it detects abnormal patterns or the goods are damaged or at risk so that he can take proactive actions to avoid problems.

- IIoT even improves the facility management process. Since the manufacturing equipment are vulnerable to wear and tear, sensors can monitor the atmosphere inside the factory which can lead to fluctuations in ideal operating conditions and alert the users for taking preventive measures.

The process of digitization in a business comes from specific vital modifications in the business operating model. And this is possible due to the digital disruption across industries. Digital has reached the business core and it is more than the addition of certain tools and technologies to the current infrastructure. Digitization is connecting devices and extracting enormous data to give useful insights for multiple purposes. Whether it is monitoring, evaluation, cost-saving on maintenance or expansion, it is giving a great ROI eventually. Thus, organizations must identify that digital is a facilitator and a catalyst that is changing the course of businesses on the whole.