Asset-intensive industries and their challenges

Companies in asset-intensive industries, including oil and gas, mining, construction, utilities, energy, healthcare, rail, and logistics, share a unique set of challenges that must be addressed to improve reliability, boost operational performance, and achieve production objectives. For these companies, the overall performance relies on their assets; while assets are out of order, the company is not making any money. On the other hand, these companies substantially require large capital expenditures and their financial performance is largely dependent on return on assets (ROA). Monitoring the performance of every asset and proactively managing the activities around each asset that is spread across a wide geographic area is another big challenge.

Major challenges that an asset-heavy company faces:

- No synergy across different processes throughout the supply chain

- Productivity loss due to unexpected breakdown or low asset utilization

- Warranty or recall costs from defective products released to the market

- Revenue loss due to operational downtime

- Imbalance between demand and supply

- Customer churn due to delayed service delivery

Why do we care?

We care because monitoring assets and making sure that they are operating to their full potential is the key to:

- Minimizing downtime and increasing productivity,

- Achieving production targets,

- Controlling costs,

- Increasing transparency across different processes, and

- Meeting organizational and corporate goals.

Asset monitoring in oil and gas – it’s critical because…

Oil and gas is one such industry wherein asset monitoring is very critical. It is essential during exploration to ensure expensive rigs are not out of order, while parts are sourced and corrective maintenance is performed. The production phase also requires asset management to minimize downtime, cut operational costs due to interruptions, and keep the oil pumping.

Right from when O&G firms start exploration, they need to track materials and services that are purchased; besides they need to maintain existing equipment and comply with health and environmental regulations. Gathering data turns out to be useful during the transition from exploration to production and the information (e.g., inventory, maintenance and safety functions, etc.) can be used to maintain and increase operational efficiency. In general, an O&G firm has to record every detail of its assets and proactively manage the activities around each asset to maintain and maximize overall site productivity asset performance.

The Internet of Things in the oil and gas industry

Forward-looking oil & gas companies believe in grabbing an opportunity provided by new technologies to increase process efficiency and gain a competitive advantage. For example, in the Eagle Ford region of North America, a new suite of technologies and improved drilling techniques enable oil rigs to produce 18 times more efficiently than in 2008, and 65% more efficiently than in 2013. New drilling techniques powered by the Internet of Things enable O&G firms to become digital and gaining more by achieving a new level of operational efficiency.

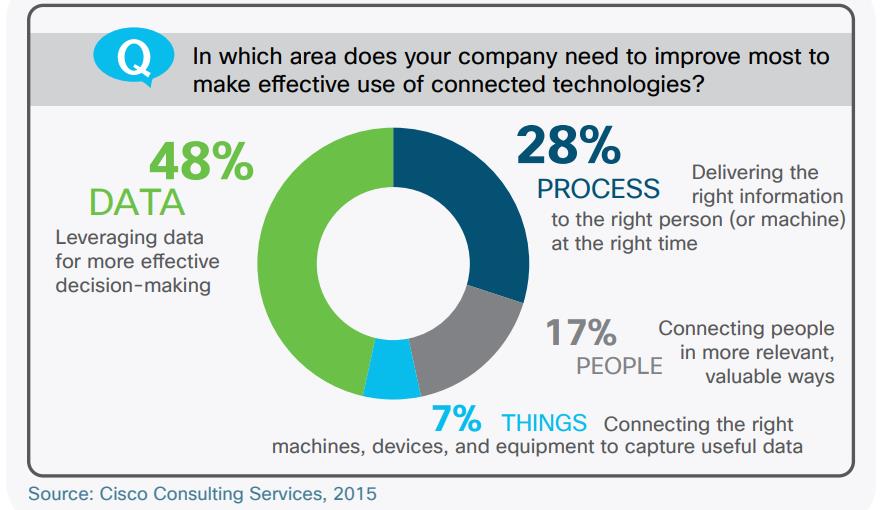

Cisco’s survey findings clearly show that IoT focuses on three major areas – 1) Data, 2) Process, and 3) People to drive digital transformation. If a company has more information on hand when needed, it can make decisions that are more effective. Although O&G firms have made significant investments in operational technology, many of them are not fully leveraging real-time operating data to improve business and functional capabilities. The survey shows that 48% of respondents think that “data” is the area where they need to improve and the next important area is “process”.

A global study by consultants Deloitte and the MIT Sloan Management Review has stated the oil and gas sector one of the least “digitally mature”.

Deploying sensors and other devices throughout operations can help firms collect data and gain rich insights to maximize business and operational benefits. Increasing amounts of machinery packed with sensors make machines visible online and enable the analysis of critical information in a way that allows O&G firms to reduce capital expenditures by up to 20%.

Data gathered from sensors and smart assets not only helps O&G firms become more reliable and efficient, but also helps create new value that ranges from dealing with unexpected well outages to increasing the amount of reserves that can be recovered from wells. An IoT-enabled asset monitoring solution can provide visibility across operations and enable firms to monitor asset performance so that they can investigate accidents remotely and eliminate unscheduled downtime. IIoT enables supervisors to identify performance and safety issues so that they can fix them before any problem affects the production in existing and new wells.

No more expensive gushers

Source :www.oilandgasiq.com

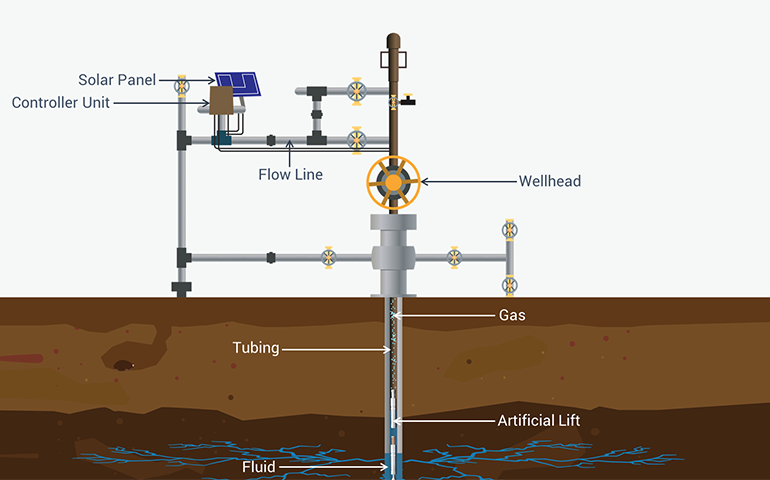

Remember this iconic image of oil drilling? We all have seen how oil strikes with a fountain high into the air! An oil well blowout has always been an expensive affair because it not only destroys equipment but also injures workers. Besides, it depends on the pressure which normally reduces with time. It means that getting oil out of the well that does not contain enough pressure requires some kind of artificial lift. In fact, a plunger used in artificial lift has now become smarter as it comes with sensors that enable O&G firms to monitor important parameters and increase production.

We are going to discuss more about plunger lift in our webinar on smart asset monitoring.

Visibility down the well

Sensors provide unprecedented visibility down the well by allowing site engineers to monitor leakage, vibration, intake and discharge pressures, vibration, and intake and winding coil temperatures. These are important parameters to monitor as a little deviation in their values can lead to severe damage and failure. Moreover, machine learning algorithms can be applied to data to derive patterns and develop predictive capabilities. Empowered by the IIoT, O&G firms can receive near real-time information about their entire operation, which is very difficult in case of fairly extreme environments where there are very little existing communication networks available. It ultimately helps firms reduce maintenance and operational costs while meeting compliance regulations and increase productivity.

Major benefits of using IoT in the oil and gas industry

- Increases the performance of assets and production efficiency

- Minimizes asset failure and downtime, thus saving costs

- Increasing the utilization of assets

- Improves asset maintenance

- Creates location intelligence

- Enhances worker safety, production, and operations

- Enhances ecological footprint

- Leads to uninterrupted production process

- Predictive analytics capabilities enable to be proactive

- Enhances supply chain planning

It takes a lot…

So just adding sensors to assets is not enough; you need to have a clear idea of what you are trying to achieve and how an IoT application is going to solve specific problems. While there are certain challenges the industry must overcome, connecting assets with IoT appears to be a necessity to maintain a competitive advantage in the global marketplace.