A lot of companies are making huge investments in AI and IoT to improve various aspects of manufacturing because these technologies have the potential to help businesses achieve more with higher efficiency by extending human capabilities. While the Industry 4.0 revolution is already underway and reshaping manufacturing processes, more recent developments in AI including improved machine learning algorithms, cloud computing, and big data are fundamentally changing the way businesses operate.

Real-time insights and predictive analytics have already started to help businesses grow their market shares faster and revenues than their competitors in different industries including manufacturing. The recent Annual Manufacturing Report 2018 by ‘The Manufacture’ shows that 92% of senior manufacturing executives believe that digital technologies like AI will help businesses boost their productivity levels and empower staff to work smarter.

Machine Learning can help manufacturing companies to reduce supply chain forecasting errors by 50% and lost sales by 65% with better product availability. – Forbes

IoT and AI bring remarkable changes and drive significant business value. If we look back, the first industrial revolution was largely driven by steam power. And today, smart sensors, big data, AI and cloud computing applications are driving the fourth industrial revolution.

Unlocking new opportunities for manufacturers

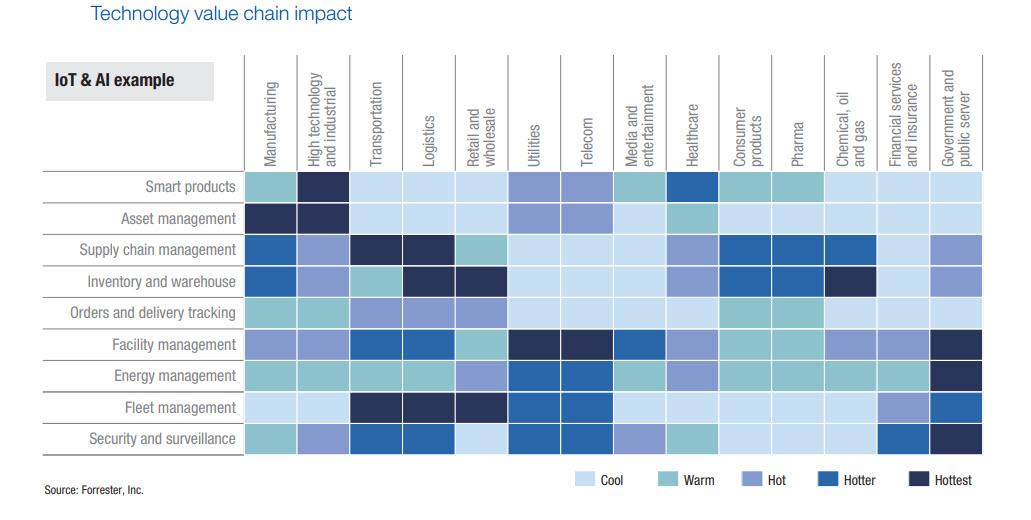

The biggest challenge in the manufacturing industry is to deliver high-quality products and services at lower costs in a minimum amount of time. Today’s market leaders are more serious about customer satisfaction and other areas that can lead them to increased revenue. IoT and AI are creating new opportunities for companies to improve services, increase efficiency, minimize downtime, and reduce manufacturing costs. With Machine learning algorithms, IoT applications, and advanced analytics, manufacturers can access to more resources and assets, gain business insights from accurate and timely data, and increase operational efficiencies and production performance. Besides, these technologies help companies to find new business models and derive new revenue streams.

Creating a new era for manufacturing

Implementing IoT is only part of the digital transformation journey to achieve manufacturing excellence, but the story does not end there. In order to realize the full potential of IoT, companies need to combine the collected data with rapidly advancing AI and ML algorithms to generate value out of the data. Ultimately, it enables manufacturers to carry out many of the day-to-day operations with utmost certainty with little to no human intervention. AI has the capability to adapt to continuously changing tasks and make recommendations that humans can trust. It can detect flaws that even most eagle-eyed human inspector would fail.

The World Economic Forum (WEF) and A.T. Kearney’s recent study of the future of production shows how manufacturers are leveraging Machine Learning and IoT to gain supply chain visibility, and optimize inventory management and improve asset tracking accuracy.

Manufacturer’s adoption of machine learning and analytics to improve predictive maintenance is predicted to increase 38% in the next five years according to PwC.

Implementing AI and IoT in your business should not be intimidating, but you need industry experts who can help you digitize your business smoothly. You can explore our smart industrial solutions and talk to our experts to know more about implementing IoT and AI in your business.