Ask yourself: Can you afford to lose 8% of your revenue due to disruption in today’s unpredictable market?

These disruptions can come in many forms, from raw material shortages to port delays to fluctuating demand or even supplier insolvency.

The impact goes beyond financial losses. Financially, you may experience lost sales, increased costs due to expediting shipments or production slowdowns, and damage to your bottom line. Logistically, disruptions can lead to stockouts, delayed deliveries, and inefficiencies throughout your supply chain. Ultimately, these issues can damage your reputation and customer satisfaction. Hence, navigating this volatile environment requires supply chain digitization.

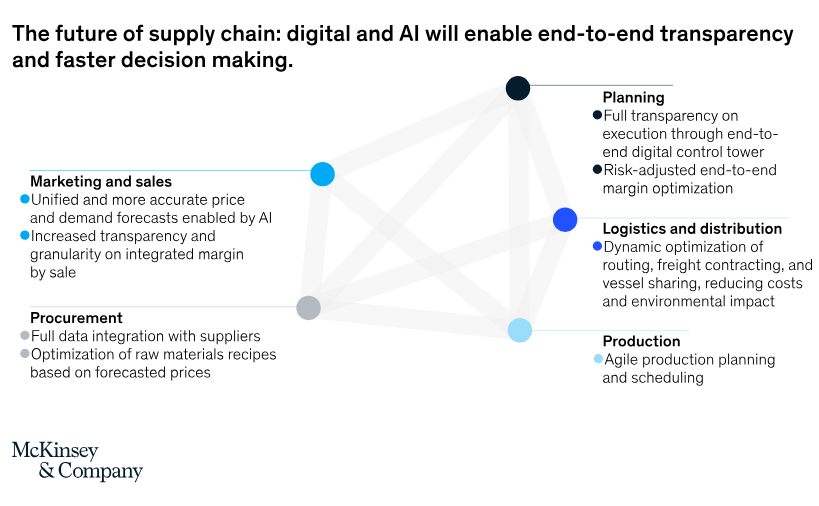

By leveraging technological advancements like artificial intelligence (AI) and machine learning (ML) to transform your traditional, siloed operations into a data-driven, interconnected ecosystem, you can gain a strategic advantage that goes far beyond mere efficiency gains.

Let’s explore the benefits of supply chain management with trending technologies.

1. Enhanced visibility and transparency

When supply chain managers cannot view real-time data across their operations, they struggle with:

- Lack of inventory visibility

- Limited traceability

- Siloed data

The GEODIS Supply Chain Worldwide Survey uncovered that only 6% of the 623 companies surveyed claimed to have achieved full supply chain visibility, despite being the third most important priority.

Solution: Implement advanced technologies like IoT, data analytics, and RFID

Supply chain digitization offers end-to-end visibility.

- IoT: You can gain real-time data on location, products, temperature, and humidity, by placing sensors on vehicles and in warehouses. This enables you to monitor and optimize conditions throughout your product lifecycle.

- Data analytics: With real-time dynamic dashboards, you can make informed decisions regarding routing shipments or inventory allocation.

- RFID: Track inventory levels in real-time. Get immediate updates on the movements of the goods.

Benefits of efficient supply chain management

- Improved inventory management

- Proactive disruption management

- Improved traceability

- Data integration

Real-life use case of digitization in supply chain with IoT, data analytics and RFID

Neele-Vat Logistics, a leader in the logistics industry, faced issues in tracking their containers. They used traditional tracking methods, making it difficult to:

- Locate containers

- Monitor container conditions

- Optimize routes

They leveraged IoT and Amazon SageMaker to gain real-time insights on the entire supply chain process. By integrating Amazon SageMaker into their operations, they gained real-time visibility and predictive insights into container tracking.

2. Streamlined operations

Are your current processes hindering your ability to respond quickly to customer needs?

Manual processes and siloed information exchange translate to wasted time, resources, and ultimately, lost revenue.

- Manual processes

- Fragmented systems

- Lack of demand forecasting

- Inefficient procurement

New Slack Research shows that around 80% of businesses using AI say that this technology is already improving their productivity.

Solution: Automate supply chain processes with cloud adoption, AI, ML, and RPA

Advanced technologies like artificial intelligence (AI), machine learning (ML), and robotic process automation (RPA) can significantly improve efficiency and productivity.

- Cloud adoption: Gain access to critical information in real-time with cloud deployment.

- AI and ML: Leverage these technologies for predictive analytics, accurate demand forecasting, inventory optimization, and procurement efficiency.

- RPA: Automate routine tasks like data entry throughout the journey of the products.

Benefits of automated supply chain management

- Increased accuracy

- Accelerated order fulfilment

- Optimized inventory

- Save operational costs

Real-life use case of supply chain digitization with cloud, AI, ML, and RPA

As one of the world’s largest aerospace manufacturers, Boeing operates within a highly complex and regulated industry. Thousands of parts, sourced from numerous suppliers around the globe, must come together with perfect precision to create a single aircraft. Traditional methods of managing this intricate network leads to several challenges:

- Lack of proper maintenance

- Inefficient management of inventory

- Difficulty in ensuring timely delivery

Boeing leveraged AI to streamline their supply chain processes. AI algorithms analyze vast amounts of data from sensors and historical records to predict maintenance needs accurately. This enables Boeing to optimize its parts inventory, reducing excess stock and avoiding shortages. Predictive maintenance ensures that potential issues are addressed before they become critical, contributing to the overall safety and reliability of Boeing’s aerospace products.

3. Minimized operational costs

Supply chain costs constitute considerable percentage of the total sales price of a product or service. These costs comprise of myriads of components, including transportation, logistics, warehousing, freight expenditure, and more. It is imperative to efficiently manage these costs in this dynamic market to avoid challenges, such as:

- High inventory holding costs

- Inefficient procurement

- Wastage and spoilage

A report by McKinsey & Company found that the use of automation in the supply chain can lead to cost savings of up to 30%.

Solution: Optimize procurement and inventory management with computer vision and AI-driven analytics

AI helps in better demand forecasting, inventory management, and logistics optimization. This, in turn, addresses the challenges related to operational costs.

- Computer vision: Automating inspection and quality control processes, reducing errors and labor expenses.

- AI-driven analytics: Enhance demand forecasting and inventory optimization to reduce overstock and stockout.

- Logistics optimization: Reduce transportation costs and delivery time with real-time tracking and route optimization.

Benefits of supply chain optimization

- Inventory cost reduction

- Procurement cost reduction

- Minimize wastage

Real-life use case of digitizing supply chain with AI-driven analytics

Coca-Cola is a global beverage giant with vast and intricate supply chain process. With operations spanned globally, the company must ensure that raw materials, packaging, and finished products move seamlessly through various stages of production and distribution. Coca-Cola encountered the following challenges:

- Shipment delays

- Longer transportation routes

- Lack of demand forecasting

To address these issues, Coca-Cola leveraged an AI-driven solution called Cola 3000. This enabled the company to gain real-time visibility into their entire supply chain operations, predict demands accurately, and optimize inventory globally. They can mitigate the delays proactively, minimize transit times, and reduce transportation costs.

4. Improved customer satisfaction

In this on-demand economy, customer expectations are not static. Customers no longer wait for weeks for their orders to get delivered. Today’s users are informed, discerning, and expects more than just a product or service. Hence, to stay competitive and ensure that your customer stays loyal to your brand, it is imperative to adopt technologies like ML and AI. A dissatisfied customer results into:

- Lost revenue

- Impact on customer trust

- Hampered brand reputation

A report from Anvyl found 60% of small and mid-sized businesses reported losses of up to 15% or more in revenue due to supply chain delays.

Solution: Real-time data to bridge the gap between customer and supply chain

You can transform your customer experience by leveraging real-time data from your supply chain.

- Real-time order tracking: Offer solutions to your customers to track order’s progress in real-time, from warehouse to their doorstep.

- Predictive delivery updates: AI algorithms help you analyze logistic and transportation data and predict potential delays. This empowers you to proactively communicate with customers to keep them informed.

- Personalized communication: You can offer personalized delivery option in case of delays or expedited shipping at no additional cost.

Benefits of leveraging ML and AI in supply chain

- Improve customer satisfaction

- Resolve customer queries aptly

- Enhance brand image

Real-life example of implementing artificial intelligence in supply chain management

Unilever is a global company with 3.4 billion daily consumers. The company faces immense challenges in efficiently deploying their products through a complex network of suppliers and manufacturers. They struggled to keep pace with real-time trends and market changes. They faced challenges, such as:

- Shipment delays

- Customer dissatisfaction

- Lack of maintaining a balance between performance and environmental responsibility

Unilever leveraged AI to combine R&D and supply chain data with manufacturing simulations. This enabled them to optimize product deployment across global suppliers and manufacturing units. Supply chain digitization enabled Unilever to optimize inventory management and streamline logistics, ensuring timely product availability and reducing stockouts. The improved efficiency and reliability have significantly enhanced customer satisfaction by consistently meeting consumer demands.

5. Risk management

Supply chain disruptions due to natural disasters, geopolitical issues, or supplier failures can significantly impact business operations.

- Miscalculated product demand

- Supply risks due to lack of raw material availability

- Socio-economic, political, governmental, or environmental issues

According to a survey conducted by Business Continuity Institute, supply chain disruptions can cause significant negative losses in terms of finances (62%), logistics (54%), and reputation (54%).

Solutions: Digital supply chain management using AI and predictive analytics

Predictive analytics models can enable you to proactively identify and manage risks.

- Proactive risk mitigation: Identify potential risks before they materialize, allowing for proactive measures.

- Resilience: Respond to disruptions quickly to minimize downtime and maintain continuity.

- Cost savings: Preventive actions based on risk assessments reduce the financial impact of unforeseen events.

Real-life example of implementing supply chain risk management with AI

Volkswagen is an automobile giant that operates worldwide. They faced significant issues with risks, such as, environmental pollution, human rights abuses, and corruption. Traditional compliance methods lack speed and latency to address such issues leading to:

- Reputational damage

- Regulatory non-compliance

The company leveraged AI-driven monitoring system based on advanced algorithms. This enabled Volkswagen to identify and analyze supplier-related news from publicly available media and social networks.

When the AI system flags any indication of a sustainability risk, such as environmental pollution, human rights abuses, or corruption, it alerts the procurement department of Volkswagen. This early warning system enables these manufacturers to assess the situation and implement necessary countermeasures promptly, supplementing traditional compliance channels with a proactive and data-driven approach.

Digitize your supply chain for business growth

Consider this:

- Are your current processes hindering your ability to respond quickly to customer needs?

- Are you making supply chain decisions based on intuition or actionable data?

- Are siloed operations slowing you down?

- Is your risk management reactive or proactive?

Technological advancements offer several benefits and pave the way for sustainable growth and market leadership. Softweb Solutions has a proven track record of offering robust solutions that enable you to gain a competitive advantage. Talk to our expert team of consultants to discuss your use case and find apt solutions for your business.

AI Workshop

Envision how your AI Journey can be in next 1-3 years from adoption and acceleration perspective.

Enroll NowNeed Help ?

We are here for you