Computer vision, just like other burgeoning digital technologies, is a significant element of Industry 4.0. However, recent advances in image processing and machine learning have enabled new use cases of computer vision in manufacturing. As modern thermal imaging-based computer vision systems consist of high-resolution cameras and AI, they have a lot to offer manufacturers.

“According to a ResearchandMarkets 2022 research, the global market for AI in computer vision will reach $73.7 billion by 2027.”

Manufacturing and industrial markets can leverage computer vision to increase safety and enhance profitability and productivity. This blog post will walk you through the real-world applications of computer vision in manufacturing.

Benefits of computer vision in manufacturing

Computer vision is becoming an integral part of various industries. There are forms of computer vision that have been used in manufacturing for years now. Although, recent trends in image processing and machine learning have welcomed innovative manufacturing use cases.

These are the benefits of computer vision in the manufacturing industry.

1. Increased Efficiency: Analyze large amounts of data in real-time to identify inefficiencies and optimize processes to increase productivity.

2. Reduced Labor Costs: Automate many repetitive and manual tasks to reduce the need for human intervention and reducing labor costs.

3. Increased Safety: Monitor workers and identify potential safety hazards in real-time to reduce the risk of accidents and improving workplace safety.

4. Enhanced Productivity: Optimize manufacturing processes and reduce waste and improving overall productivity.

5. Enhanced Customer Satisfaction: Improve quality control and reduce the risk of producing faulty products to improve customer satisfaction.

How computer vision can transform the manufacturing industry

Computer vision development has gained traction in the manufacturing industry. The role of AI in computer vision has garnered the attention of many businesses.

Let’s look at the top 9 use cases of computer vision in manufacturing.

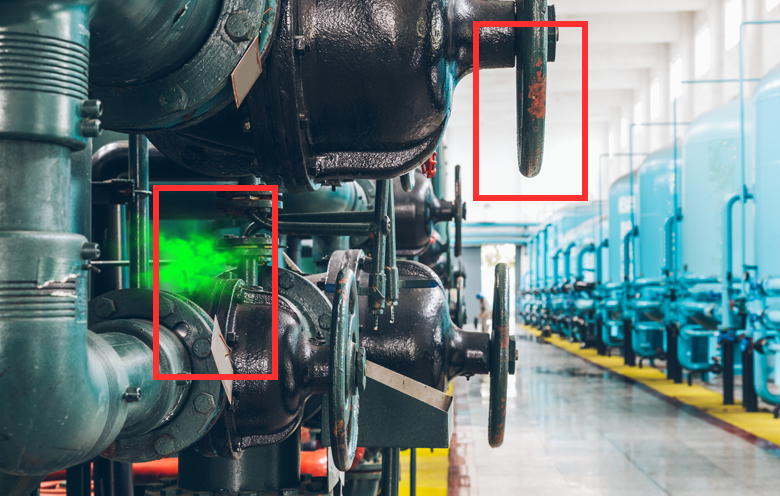

1. Leak detection

The traditional method of detecting oil, vapor, or liquid leaks from plant components is unsafe, error-prone and labor-intensive. With computer vision, industrial companies can monitor and spot leaks more accurately and safely. AI-powered cameras have the potential to monitor and automatically detect leakage in real-time. Also, upon leakage detection, a notification is emailed immediately to the concerned authority.

Let us consider a scenario: A chemical processing plant with several pipelines transports toxic gases or liquids. Leakage from any such pipeline can pose a serious threat to operators with conventional condition monitoring. Therefore, a computer vision-based leakage-detection mechanism can save manufacturing companies from mishaps. With this technology, the chemical plant is able to monitor and localize leaks more quickly, safely, accurately, and remotely.

2. Corrosion detection

In heavy industries, corrosion (rust) poses a substantial threat to workers’ operational safety. Also, the traditional process of detecting and identifying corrosion by human interpretation is subject to error. Computer vision can constantly monitor and automatically detect corrosion. It enforces the deep learning approach to automating the corrosion detection process. Thus, it can help manufacturers reduce human risks and associated costs.

For instance, a mining company with large steel structures requires checking the structures frequently for corrosion. The manual process of rust detection may take a couple of weeks/months, depending on the size of the plant. Using machine learning-based computer vision techniques, the mining company effectively identified corrosion. Also, upon rust detection, the system sends an instant alert to managers for maintenance activities.

3. Product assembly

The manual product assembly process takes a lot of time and is quite expensive. However, the growing role of automation in the manufacturing space is replacing these traditional methods with fully automated systems. Tesla has already automated 70% of its manufacturing processes. AI-powered computer vision techniques can help manufacturers automate their product and component assembly processes.

Furthermore, it enables them to maintain their packaging standards while maintaining accuracy and saving time. For instance, a soft drink filling plant must verify if bottle cap closure or bottle packaging is correctly conducted or not. Computer vision automated the entire process and ensured that the bottles were precisely packed.

4. Defect detection

Let’s understand this with an example. During production, a sunflower oil production company was facing the issue of damaged bottles. The manual process of detecting defects was costing them a fortune and causing trouble during transportation. Thus, they embraced visual inspection based on computer vision technology. It enabled them to detect defects instantly and get notified in real-time.

5. Inventory management

A manual inventory management process requires a significant number of human resources. Generally, a manufacturing firm faces several issues like misplaced inventory, stockouts, employee errors, excess inventory, etc. Using computer vision powered ai drones, manufacturers can automate inventory monitoring and management processes. It lets them avoid stockouts, track inventory movement accurately and count inventory automatically.

As an illustration, let us consider a manufacturing inventory where managing, placing and keeping track of stocked goods is difficult if done manually. However, an AI-based computer vision method helped them outdo their human counterparts by enabling their inventory management team to:

- Spot misplaced items in no time

- Ensure timely and systematic actions

- Receive alert notifications in real time

- Make informed and timely decisions

6. Stock counting

The biggest threat for any manufacturing company that operates on a conventional inventory counting method is losing track of stocks. Embracing computer vision, manufacturers can get a real-time count of products and automate the inventory stock counting cycle. It eliminates the need for workers to conduct manual counting, thereby reducing the error rate and time consumed.

For example, in a factory plant, workers count the number of products on a conveyor belt, which is labor-intensive and cumbersome. Hence, to save time and energy, it is advisable to adopt thermal cameras that instantly identify products for stock management. It is possible to count products automatically using computer vision.

A complete guide to computer vision for quality control in manufacturing

Whether you want to learn how to design a computer vision system for quality control (just by following six steps) or know how to use computer vision solutions for quality control in manufacturing, your answers are just a download away from this whitepaper.

7. Barcode analysis

In today’s world, barcode scanning has become a cornerstone for identifying products. Barcodes make identification easy. In the manufacturing industry, firms must ensure that they obtain precise barcodes before releasing products, such as types of machinery. It is one of the most secure use cases of computer vision in the manufacturing industry.

8. Packaging standard

Computer vision can be used to verify that products are correctly packaged and labeled, reducing the risk of errors and ensuring compliance with regulatory requirements. This is done by training the computer vision system to recognize the specific attributes of a correctly packaged product. These attributes include position and orientation of labels, the presence of safety seals and the correct packaging materials. The system can then compare the attributes of each product as it moves down the production line with the expected standard and alert operators if any deviations are detected.

9. Predictive maintenance

Computer vision can be used to monitor machines and equipment in real time, detecting signs of wear and tear before they cause a breakdown. This can help prevent costly downtime and repairs. The system can be trained to recognize the specific attributes of normal machine behavior, such as sound and vibration patterns, temperature readings, and power consumption.

If the system detects any deviations from expected behavior, it can alert operators to the potential issue and schedule maintenance or repairs before the equipment fails. Additionally, computer vision can be used to monitor the condition of critical components, such as belts and bearings and detect signs of wear and tear that may require replacement. This can help extend the lifespan of equipment and reduce maintenance costs over time. This makes predictive maintenance the major attribute of computer vision in the manufacturing industry.

Explore Which computer vision trends should modern enterprises adapt to in 2023

Unlock new intelligence with computer vision!

With the emergence of smart products and innovative technologies, computer vision has taken center stage. Manufacturing enterprises across the globe are embracing modern computer vision techniques for better operational efficiency, safety and higher productivity. If you want to incorporate computer vision into your manufacturing processes, you can get in touch with our machine learning experts.