Customer background

The client is a leading logistics company based in the United States. They specialize in providing sustainable packaging solutions. With more than two decades of experience in the industry, they have built a reputation for delivering high-quality, reliable packaging and logistics services. They operate an extensive network of storerooms where they receive, sort, pack, and ship goods for distribution to retail stores and other warehouses.

Challenges

With a vast network of warehouses and a huge volume of daily operations, our client wanted to improve their packaging and warehousing processes to maintain a competitive edge and meet increasing customer demands. Their main challenge was ensuring accurate and efficient packaging while maintaining product safety.

- Package classification and quality control: Manual sorting and inspection of packages was time-consuming, prone to errors, and inefficient.

- Package counting: Manual inventory counting was labor-intensive, error-prone, and inefficient, especially during peak operational periods.

- Packet seal and anomaly inspection: Ensuring the integrity of package seals and detecting physical anomalies manually was difficult, inconsistent, and inefficient. This led to potential product damage or loss during shipment. Sometimes damaged, or improperly packaged items were even shipped.

- Inventory management: The conventional inventory tracking methods were inefficient and led to repeated differences and stockouts.

- Operational efficiency and data utilization: The overall workflow lacked automation, which caused delays in order processing. The existing system was not capable of utilizing the vast amount of data generated daily and did not facilitate informed decision-making.

Solutions

Our team of experts conducted thorough discussions with the client’s teams. We understood their challenges and worked on finding appropriate solutions. To address their issues, we proposed and developed a comprehensive solution integrating computer vision, artificial intelligence (AI), and Vision AI. The solution included:

Package classification and quality control

Implemented a computer vision system to automatically classify packages based on their size, shape, and type. This system used high-resolution cameras and AI models to accurately identify and categorize packages, ensuring they were sorted and inspected correctly for storage and shipment. Leveraged MLOps to continually improve the classification algorithm by learning from new data, enhancing the system’s accuracy and efficiency over time.Package counting

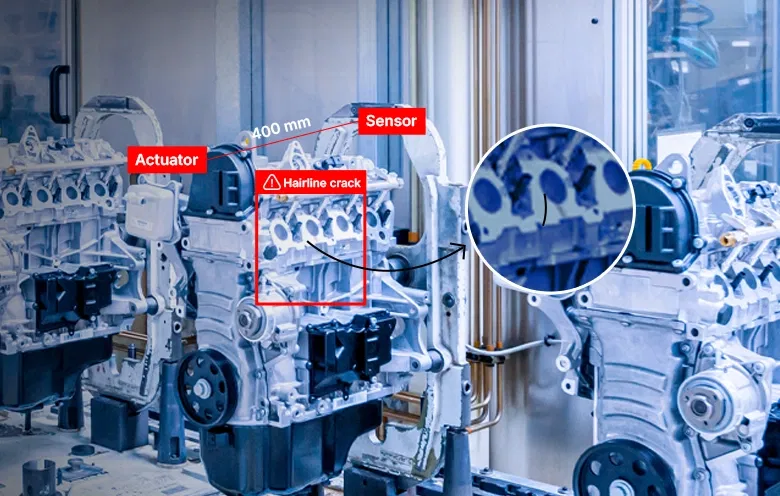

Developed a real-time package counting system using AI and computer vision. This system utilized cameras placed along the conveyor belts to count packages as they moved through the warehouse, providing accurate inventory counts and reducing manual counting errors. Employed Vision AI to analyze the flow of packages and ensure that counts were precise even during peak operational periods.Packet seal inspection

Implemented a system to inspect packet seal anomaly using computer vision. High-resolution cameras and AI models detected defects, ensuring that all packages were properly packed and securely sealed before shipping. Vision AI enhanced the system’s ability to detect and categorize several types of anomalies, improving overall quality control.Smart inventory management

Developed an application for real-time inventory tracking using AI and computer vision. Cameras and sensors were placed strategically to monitor inventory levels, track item movements, and update the inventory database automatically.Data-driven decision making

Implemented AI and ML models to analyze the vast amount of data generated, providing actionable insights, and enabling data-driven decision-making. This included predictive maintenance for machinery, optimizing routing, and improving logistics. This also helps predict inventory needs based on historical data and trends, optimizing stock levels, and reducing stockouts.

-

Industry

-

Technologies / Platforms / Frameworks

Computer vision, AI, Python, OpenCV, TensorFlow, Azure cloud for MLOps

-

Benefits

- Automated classification and inspection ensure correct sorting and shipment, with MLOps continually enhancing the system’s accuracy. High-resolution cameras and AI models minimize human error, leading to reliable package handling.

- Real-time package counting ensures precise inventory counts, reducing overstocking and stockouts. Automation saves time and labor costs by minimizing the need for manual counting. Vision AI maintains accurate counts even during high-traffic periods.

- Detecting seal defects ensures securely sealed packages, reducing damage and tampering. Vision AI enhances the ability to identify and categorize anomalies. Securely sealed packages lead to higher customer satisfaction.

- Continuous monitoring of inventory levels and movements ensures real-time updates. Computer vision enhances coordination between workers and machines, improving operations.

- AI and ML models provide insights for informed decision-making, optimizing operations. Early identification of machinery issues reduces downtime and maintenance costs. Data analysis helps optimize routing, logistics, and inventory levels, enhancing efficiency.

Decades of Trust & Experience

1630+

Projects

545+

Experts

26+

Products and Solutions

1020+

Customers

Similar Case Studies

Consolidated acquired product catalogs into a unified PIM for a global semiconductor leader

Enhanced quality control system for a manufacturing company with machine learning

Automatic defect detection on semiconductor wafer surfaces using deep learning

Connect Now

Our experts would be eager to hear you.